Quality Control

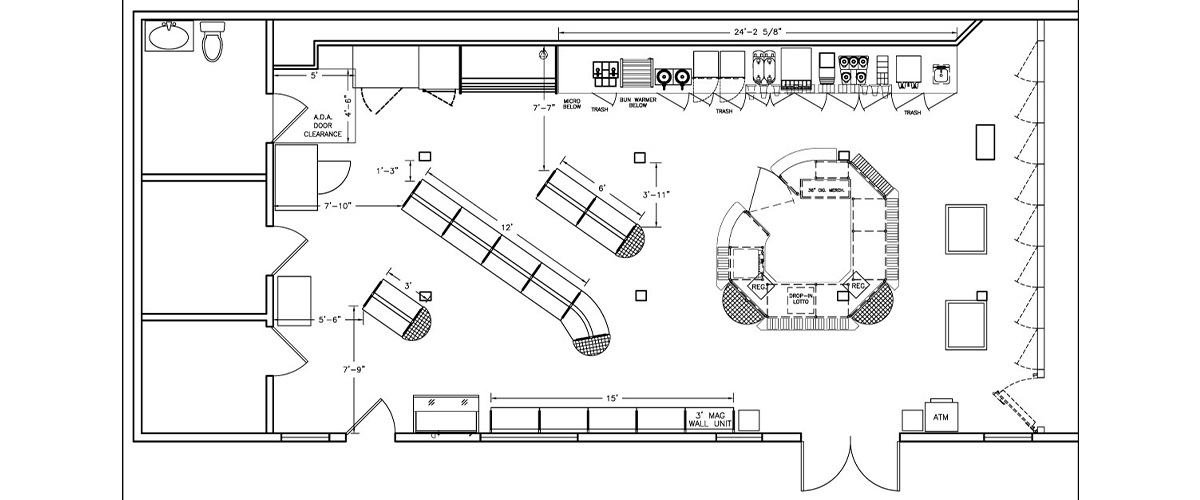

1. Determine store layout

Professional store layout planning can effectively guide customer flow and enhance consumer experience through traffic flow design and space zoning. At the same time, it can accurately calculate the type and quantity of display devices required for each area, providing a complete visual marketing solution for the retail space.

2. Pre-shipment inspection

We have established a strict factory pre-installation test process. Before product packaging and delivery, a professional team will conduct a complete simulated assembly test on all display furniture based on the final confirmed store layout plan or 3D rendering. This pre-installation process can truly restore the customer's on-site installation environment. Through a systematic quality inspection procedure, we can effectively identify potential assembly problems or structural defects. In a controllable factory environment, we can discover and solve more than 90% of installation risks in advance, and at the same time compile a detailed installation guide based on actual measured data to ensure that customers receive a verified installation plan and zero-defect product delivery.

The key point of pre-installation process

- Rationality and durability of the installation structure

- Difficulty level of installation

- Matched level of hardware accessories

- Lighting, wiring and transformers work normally

- Checking surface and workmanship defects

- Double-check of the joinery items and their quantities

- ETC

3. International standard packaging

We provide full-process logistics management services, using professional shockproof packaging technology and standardized transportation solutions to ensure the safe delivery of each customized display stand and accessories. We track the entire process from leaving the factory to the installation site, and through a strict quality control system, we ensure the integrity of the product during transportation and achieve zero-loss delivery.

1. Stretch Wrap

2. Corner Protector

3. Corner Protector Detail

4. Foam Wrap

5. Bubble Wrap

6. Plywood Box with Pallet

4. Inspection and delivery

Zhongxin Display strictly implements the ISO quality management system and implements full-process quality control from raw materials to finished products. We use military-grade protective packaging technology and provide high-definition cargo images for customers to review before shipment. Customers are especially welcome to visit the factory for inspection. We will cooperate throughout the process and provide professional reception services to ensure that each exhibit perfectly meets your quality requirements.

5. Quality Assurance

We are fully aware of the uncontrollable risks of sea/air transport. We have established a comprehensive emergency response mechanism for any damage that may occur during transportation or installation (even if the probability is extremely low). Please provide clear images of the damaged product in a timely manner. Our professional team will evaluate the situation as soon as possible and develop the best solution for you through internal technical meetings.

Quality Guarantee for Display Fixtures

Warranty period: 3 months-6 months after receiving the cargo, on the premise of no man-made damage, please contact our sales consultant, we promise the solutions will be submitted within 1-3 days .

LED lighting, Hardware, Graphics and etc

Warranty period: One year after receiving the cargo.

Service Network